Fermentation is at the heart of brewing beer.

It is a process in which yeast converts maltose and glucose in sweet wort to ethyl alcohol and carbon dioxide (CO2) and generates various esters contributing to the unique flavour profiles of different beer styles. This process is essential for consistently creating taste and aroma that distinguishes the diverse character of craft beer.

To maintain this consistency and quality, breweries increasingly rely on digital data collection systems. This approach allows for precise tracking of critical variables like temperature, pH and gravity, enabling brewers to make informed, data-driven decisions that ensure high-quality beer with consistent flavour profiles.

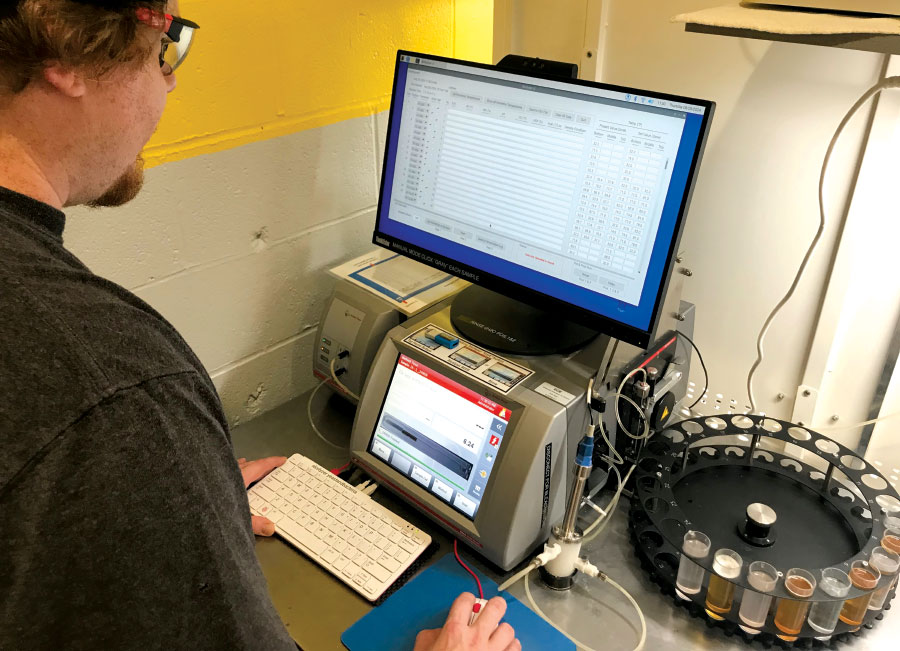

In most modern breweries, daily “at-line” fermentation data collection is the standard, typically accomplished manually. Methods used to collect and analyze data can vary widely, from traditional pen-and-paper recording using classic hydrometers to the use of sophisticated and expensive density measurement systems. However, the shift to continuous in-line monitoring represents a significant leap forward, providing brewers with real-time, high-resolution insights that far exceed the limitations of periodic, discrete sampling methods from the past.

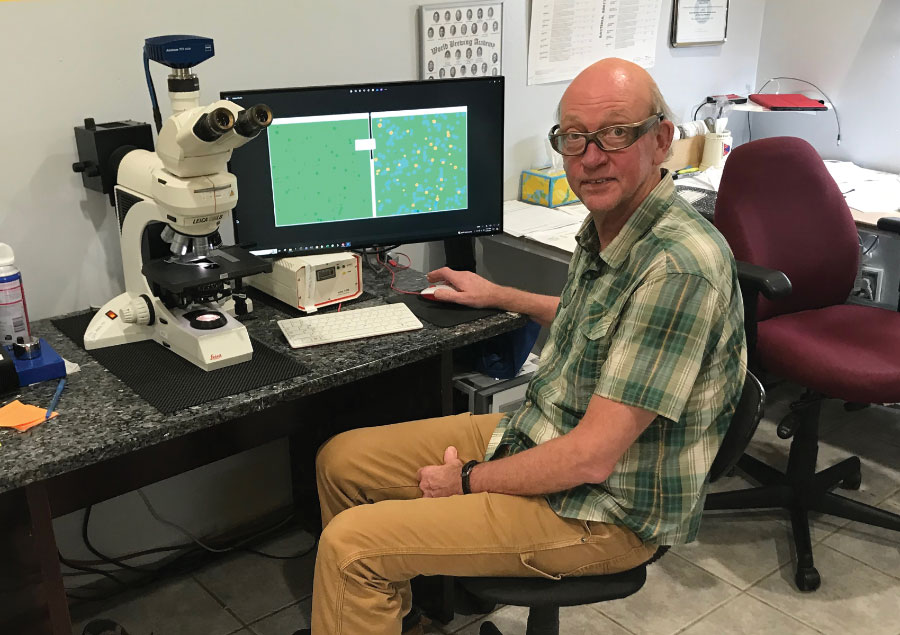

Lord Hobo Brewing Company in Woburn, Mass., believes so strongly in perfecting the fermentation process that the brewery brought an experienced microbiologist with a passion for combining art with science and technology on board.

“There are no clipboards in my lab,” said Matt Cottrell, quality manager and microbiologist at Lord Hobo. “Fermentation is so important to this brewery; we don’t take any chances with the data. We use sensor technology, laboratory instrumentation and the Internet of Things [IoT] to analyze samples every single day.”

After joining the Lord Hobo team, Cottrell developed an intelligent software application that integrates with the brewery’s existing tank temperature sensors via a cloud-based application programming interface. This software analyzes the data at a macro level, with a specific focus on tracking fermentation progress. The results are automatically published to shared Google spreadsheets, making the data instantly accessible to the entire team, including production managers, brewers, and cellar operators in the brewery.

The platform also enables the scheduling of sample collections and the creation of historical fermentation data sets, and ultimately ensures consistency and quality of collected data. “Automation eliminates the possibility of human error,” Cottrell said. “There is no error in transcriptions, no transposed numbers and the data can be shared across the entire production team and even with other facilities, if needed.”

Lord Hobo is uniquely positioned for success, as every fermenter and bright tank in the brewery is equipped with multiple temperature sensors continuously monitored by the sensor technology-driven IoT system. This setup provides Cottrell with unlimited, real-time access to information across all the brewery’s tanks, organized centrally in his lab. “Having access to the temperature data alone is incredibly powerful,” hesaid. “I know which fermenters need to be sampled each day, which fermentations are on track and which may need corrective action.”

Temperature control is crucial at each stage of fermentation, directly influencing the final product’s quality. Continuous monitoring provides real-time insights, enabling brewers to be more proactive and efficient. This ensures optimal conditions for yeast activity and smooth progression through each fermentation stage.

At Lord Hobo, a list of samples is generated daily at five in the morning using Cottrell’s software, which monitors tank temperatures and identifies those within the active fermentation range for sampling when workers arrive an hour later. The collected samples are then hand transported to the lab for Cottrell to analyze using a digital density meter coupled with an alcolizer. His software then combines the sample data with the previously collected temperature data and automatically generates results that publish to a shared Google sheet.

By the end of the first day of data collection, the optimal timing for dry hopping can be determined based on sugar consumption levels and yeast activity. This timing is crucial for achieving consistent flavours. The data also provides a clear curve of sugar consumption, which is why active fermentations are sampled daily.

Why automation is important for beer fermentation

The primary reason for using sensor technology during fermentation is to ensure consistency, particularly when brewing various flavours and craft beer varieties.

It’s also vital for maintaining healthy fermentation. If fermentation doesn’t begin promptly, it can compromise the beer’s quality and consistency. Automation plays a critical role in safety as well, ensuring the fermentation process completes properly, as uncontrolled fermentation in a keg or bottle can lead to CO2 buildup and a potential explosion. Consistently tracking fermentation over time also simplifies the creation of guidelines or templates for future beer production.

“We can expect that beer production should follow a certain time course,” Cottrell said. “If it starts deviating from that schedule, there are certain corrective actions we can take. Collecting and monitoring the data daily helps to create a history so that, over time, we have a specific template to follow. Things can go wrong, so you still must pay attention, but automation plays a major role in developing that consistent playbook.”

The primary reason for using sensor technology during fermentation is to ensure consistency, particularly when brewing various flavours and craft beer varieties.

Predicting how beer will ferment is challenging, but with time, automation helps to develop a tolerance guide. By establishing a daily range, operators can identify deviations and make necessary adjustments to either energize the yeast or slow down the fermentation process.

Without automation, valuable time can be wasted in the cellar trying to re-engage yeast with the sugar. When yeast settles at the bottom of the tank, it sometimes must be resuspended to regain contact with unconsumed sugar, which can delay the process. Automation helps to catch these anomalies early and track data to create precise schedules.

Sensor technology is also intuitive, user-friendly and requires minimal training. Operators receive alerts and notifications on mobile devices, allowing everyone in the brewery to stay connected daily. Automated systems enable accurate monitoring of critical fermentation parameters like temperature, pH and dissolved oxygen levels. Maintaining these within strict tolerances ensures consistency in taste, colour and quality across batches.

Finally, automation reduces the variability that can result from manual interventions, helping replicate the same conditions for each batch. This consistency is crucial for maintaining brand reputation and consumer trust.

Aaron Ganick is a serial technology entrepreneur and the founder and CEO of Preddio Technologies, the parent company of BrewOps. Aaron holds a degree in electrical engineering from Boston University and has authored dozens of granted patents in the fields of optical networking, telecommunications and automation systems. He can be reached at aaron.ganick@brewops.com. For more information on BrewOps, visit brewops.com.